Outsource Finite Element Analysis (FEA) Services

Your concept looks great on paper, but will it stand loading conditions in reality? You are sure that the design you have in mind will withstand the structural loading, but how will the product behave when both thermal and structural loading occur simultaneously? You have a tight budget; would you like to reduce the amount of experimental testing? R RADIANT ENGINEERING (R RADIANT ENGINEERING) can help you solve these problems and meet your product requirements through detailed product testing

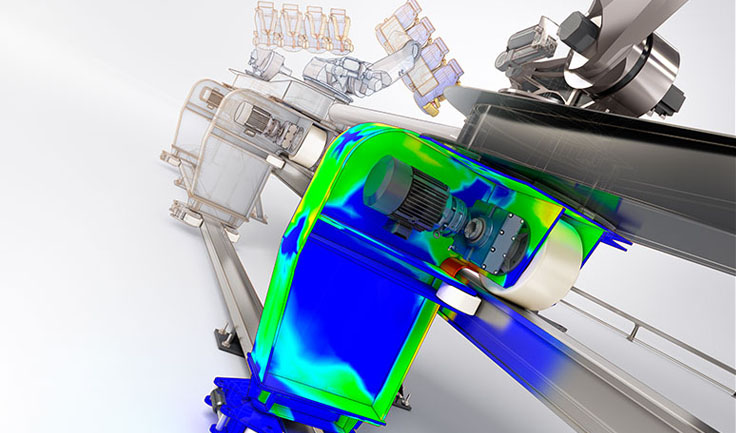

Finite Element Analysis (FEA) improves product quality, and is now extensively used in the industry to verify, validate or test design, and is proven to reduce design cycle time significantly by eliminating errors. It increases product reliability through running a greater number of test cases / design configurations and helps increase confidence in a product's performance

Our FEA Services

- Structural Analysis

- Modal Analysis

- FE Modeling

- Linear and Non-linear Static Analysis

- Dynamic Analysis

- Thermal Analysis (Steady State and transient)

- CFD

- Mould Flow Analysis

Using simulation effectively will streamline the product development process and help turnaround a greater number of products within the same amount of time when compared to the traditional design process.

The Team and Approach

At R RADIANT ENGINEERING, we have a team of qualified and experienced mechanical engineers who are capable of conducting various types of analysis such as structural (fatigue, strain, stress, and deformation), thermal (radiation, conduction and convection) fluid flow (velocity, pressure and flow) and coupled field analysis. We have worked with several global engineering companies and have provided a wide range of FEA solutions to them. A few examples of our work are listed below -

- Port design optimization for an automobile engine valve using thermal – fluid flow analysis

- Moldflow analysis to detect hotspots, pressure loss, warpage and optimization of gating and risers / runners for a consumer goods plastic part

- Normal mode analysis of a structure under thermal loading

- Critical frequency analysis of motor components under thermal and structural loading

We also work with our customers to find feasible design solutions. By integrating FEA into the design process, optimization of materials used can be done with ease. Companies in the aerospace, automobiles and biomechanical industries use our FEA services to understand how structures bend, twist or experience stress. Our FEA services include suggesting design options based on FEA results as well.

The mechanical engineers at R RADIANT ENGINEERING have a rich experience of over ten years in solving complex mechanical engineering analysis challenges, such as coupled field analysis and explicit dynamics. Moreover, they are well-versed in using FEA in mechanical designs. With in-depth product development knowledge, real world experimental testing skills and software tools expertise, you can rest assured that the FEA solutions our company provides come with a high degree of confidence and understanding.

Benefits of Our FEA Services

- Reduction in field failures and product recalls

- Decrease in ECOs and ECO processing time

- Increase in productivity

- Reduction in number of prototypes needed

- Reduction in physical tests

FEA Software and Tools Used at R RADIANT ENGINEERING

- Ansys

- Hypermesh

- LS-DYNA

- CosmosWorks

- MSC Nastran